Menu

-

-

F.A.Q

- How to identify genuine agarwood chip, natural or cultivated

- How to identify oil injection / absorption fake agarwood beads

- How to know if there are more than one oil in your oil

- How to make your wood bracelet or mala darker

- How to tell if an Agarwood bead sinks WITHOUT sinking it under water?

- How does back flow incense work and how do you burn it?

- Where to start if you don't know what agarwood is ?

- Why are you losing money if you buy seeds and plants?

- Which agarwood incense should I choose?

- Frequently Asked Questions

- Agarwood Related Articles

- Shipping

-

SHOP - Agarwood

-

SHOP - Other Fragrant Wood

-

SHOP - Incense Holder and Burner

-

- FREE guide book

- Testimonials

- "Why did you buy this?"

- Contact us

- About Us

- +61430284329

- Login

-

English

Can flavour chemists truly synthesise agarwood?

January 05, 2022 7 min read

Table of Contents:[hide]

Let me begin with a true story.

“Why is there dust on my ice cream?”

When I was a student, I used to work in a 5-star hotel located under the Sydney Harbour Bridge. One busy night, a guest ordered a Vanilla Icecream to be brought to his room (room service). I brought the ice cream up for him.

Around 5 minutes later, he called and complained to me: “Why is there dust on my ice cream?”

At first, I thought I had done something wrong, or it could be something that accidentally fell into his plate. I apologised, then went up to collect the meal. The customer left the tray outside his room. I opened the tray and saw many black tiny spots on the ice cream.

Immediately I knew this was a misunderstanding. The customer must have thought these tiny black spots are “dust”. This “dust” was from ground Vanilla beans. Our Chef mixed these ground Vanilla beans with milk and other ingredients to make this Vanilla Icecream. I had a chance to this ice cream with the real Vanilla bean. Maybe the Chef’s words influenced me; I did feel the taste was buttery, creamy and earthy besides the classic Vanilla flavour.

Anyway, It was a busy day, and I had many pending orders, so I did not have time to explain this to the customer. Besides, he had already placed his tray on the floor outside his room. Asking him to take it back was not really a choice.

I brought the ice cream down and showed the Chef. He shook his head and prepared a new bow. He took out an ice cream bucket from the fridge, scooped out 2 scoops of ice cream on the new plate. The chef says humorously: “Today, the $7 supermarket ice cream is better than our in-house specialty. Bring this back to the customer, and he will be happy.”

I brought the freshly prepared ice cream to the customer, and he was happy with a replacement. He even gave me a tip later.

I told our Chef what happened and here was what I learned from him

- It costs around $45 to make 1kg of Vanilla Ice cream in-house, with real Vanilla compared to a $7 ready-made Vanilla flavour 1-kg tub. The hotel has both products which are used for different purposes (price is indicative only)

- The hotel usually serves delicate, chef-made ice cream because it is a 5-star hotel. After all, it is a point of difference.

The customer did not appreciate the real vanilla bean because it was partly my fault. After all, I assumed he knew the dust was actually the ground Vanilla beans. If I had had not made that assumption, I would have told him at the time of delivery. Maybe there would be no food waste

What would happen if the customer was a food aficionado (food lover)?

Perhaps he would write a thank you note or even tip me for providing outstanding service. I said that because my colleagues had received many compliments about the same in-house specialty ice cream.

My colleagues also told me that if I had explained to the customer that the black spots were not “dust” but fine Vanilla beans, he could have appreciated the hotel’s special made.

.

Why am I telling you all this?

Most people know the Vanilla flavour, and most people love it, including kids.

The demand is high. Real Vanilla bean is costly. Generally and ideally, manufacturers try to get the cost as low as possible without affecting the quality of their goods. On the other hand, generally, consumers want a deal: to get what they think is the highest quality at the lowest price.

Unfortunately, Vanilla bean supplies are unstable, so flavour chemists synthesise Vanilla.

Many food flavouring companies synthesise Vanillin (the main chemical component that gives you the Vanilla’s flavour) from petroleum sources. Although Vanillin is recognised as safe, some consumers do not feel right when they see the word “petroleum”.

So a company Evolva comes up with a synbio method to create it from yeast which I think is brilliant.

Synbio is an abbreviation for Synthetic Biology

Synthetic biology is the design and construction of new biological entities such as enzymes, genetic circuits, and cells or the redesign of existing biological systems (EBRC)

With this technology, flavour chemists can tweak some genes of a yeast to produce a substitute that is costly and hard to produce or add new features to the existing one:

- Microorganisms harnessed for bioremediation to clean pollutants from our water, soil and air.

- Rice modified to produce beta-carotene, a nutrient usually associated with carrots, that prevents vitamin A deficiency. Vitamin A deficiency causes blindness in 250,000 - 500,000 children every year and greatly increases a child's risk of death from infectious diseases.

- Yeast engineered to produce rose oil as an eco-friendly and sustainable substitute for real roses that perfumers use to make luxury scents.

Synbio Agarwood

Evolva has also tried to synbio agarwood oil in the lab. It was expected to be available in 2017

https://www.synbiowatch.org/commodities/agarwood-oil/

When writing this article, it is 03.01.2022,I have not found it to be available. Maybe it is known to certain people only.

But even it is available, I think there would be one type of agarwood aroma are available. Anyway, I am keen to try this synbio agarwood oil when I can.

One property that synbio agarwood oil is probably lacking

Both you and I know this: besides the divine aroma, hydro-distilled (essential oil) and Co2 extract agarwood oil are antibacterial in nature.

The synbio technique uses a particular type of yeast that feeds on sugar to produce agarwood flavour. Yeast is microorganisms (or bacteria); would it survive in an antibacterial environment?

Unless the yeasts are mutants, the chance of survival is low.

Hence, they may create some agarwood aroma, but not other properties such as antifungal and antibacterial.

Synbio agarwood might only have one aroma profile.

Supposed that one day, flavour chemists could create mutant yeast, can they really make an agarwood aroma profile or at least imitate one?

Even if the synbio is successful, creating similar scent profiles of all agarwood smells will be challenging.

Here is why

Agarwood oil contains hundreds of scent molecules besides ß-agarfuran, but synthetic agarwood oil gets its aroma from one or two compounds in agarwood (for example) ß-agarfuran). This explains why plant-derived agarwood oil has a more complex aroma and why synthetic agarwood oil may lack of depth.

If you look at the below table, there were five major chemical compounds in High-Quality Agarwood Oil which has more than 200+ compounds in total

(Source: Ismail et al 2015)

(Source: Ismail et al 2014)

Synbio companies could only manufacture one component but which one do they choose?

Maybe they could do more than one in the future. But for the time being, you will not get the same experience as Oud oil from plant-derived agarwood.

Just in case you are not aware, sometimes the aroma that you smell is not from one compound but many.

Let's take a look at an example

The taste of chocolate

In 2006, at the Technical University of Munich, Professor Peter Schieberle, Felix Frauendorfer and his team found that there are only 24 compounds that are related to the taste of chocolate. No individual compound was identified bearing the typical aroma of cocoa.

Source: World Cocoa Foundation

Individually, these compounds smell like: caramel, sweaty, rancid, cooked cabbage, potato chip, honey, and malty. However, if these components combined, the compounds will give you the taste of chocolate.

Does that mean to synthesise agarwood biologically, the flavourists need to synthesise all of the aromatic compounds of Agarwood?

If that was the case, maybe distilling real agarwood is easier and cheaper.

In short, synthetic oud has its place in the fragrance industry, but it will not replace plant-derived agarwood completely.

On a side note, synbio companies use fermentation to synthesise one key component of a plant.

In the case of Vanilla, flavour chemists feed their special yeast with sugar. Vanillin is created during this process, and the yeasts’ cells and genes are removed during production. So only Vanillin is left.

Isn’t it amazing? People can create Vanilla flavour from sugar cane ! Evolva did an excellent job.

But with Agarwood, as agarwood growers, we do not create it from sugar cane because we do not know how to.

And as agarwood farmers, first we plant the tree, then we use fermentation to enhance “flavours” in agarwood.

The fermentation process happens without added yeast and sugar because there is enough sugar and bacteria in the pulverised wood and water. So the natural yeast is already there.

What happens to the natural yeast after extracting/distil the Oud oils?

Almost all yeast will die. We use two main methods in our distillation— Co2 extract and Hydro-distillation.

CO2 acts as a cleaning agent to eliminate most moulds and microbial bacteria, including yeasts.

Hydro-distillation uses steam which also kills mould and bacteria.

Only aromatic, 100% pure Oud oil remains.

Finally, Agarwood oil is high in Sesquiterpene which is also antibacterial, and it is recognised as safe to use (Essential Oil Safety: A Guide for Health Care Professionals page 190)

Oud oil that uses fermented ground agarwood

One of Oud using fermentation process is The Peated Oud.

Fermentation and heating the pulverised agarwood create intense smooth woody profile.

When it goes through Co2 extraction process it develops a thick body, and high viscosity. I think it will be a real challenge for perfume chemists to synthesise this Oud oil.

P/S:

Here is a good one:

Did you know there is a Vanilla note in Agarwood chip?

If you know what vanillin smells like, you will find this smell when heating agarwood chips. It is because agarwood chips contain Vanillic acid, which flavour chemists use to extract Vanillin.

In short, in theory, a flavour chemist could synthesise or extract vanillin from Agarwood. But in reality, he probably would not do that because it costs more than Vanilla Beans.

I believe there are enough Vanilla beans and Agarwood lovers who appreciate the flavours of the real thing. So synthetic and synbio flavours will not replace original plant-derived flavours completely.

Leave a comment

Comments will be approved before showing up.

Also in News

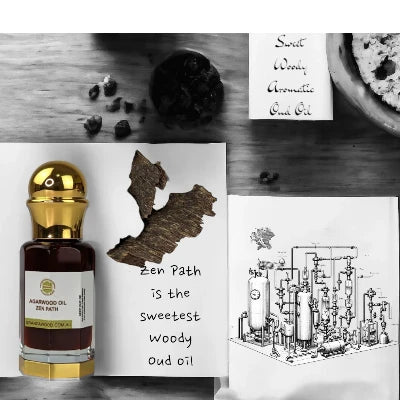

Anoint with The Zen Path, and you will never yearn for the artificiality that numbs the senses

March 03, 2024 2 min read

You say: “Your Agarwood is too expensive”. Let’s Reason Together - about Price

February 14, 2024 8 min read